Autre convoyeur Putzmeister Sewage sludge conveying system

Si vous décidez d'acheter un véhicule ou du matériel à bas prix, assurez-vous que vous communiquez avec un vendeur réel. Cherchez autant d'informations sur le propriétaire que possible. Un escroc peut se faire passer pour une société réelle. En cas de doute, contactez-nous en utilisant le formulaire de commentaires afin que nous effectuions un contrôle supplémentaire.

Avant d'effectuer un achat, étudiez attentivement plusieurs offres de vente afin de connaître le coût moyen du modèle de véhicule ou d'équipement que vous avez choisi. Si le prix de l'offre qui vous intéresse est très inférieur aux offres similaires, réfléchissez bien. Une différence de prix considérable peut indiquer la présence de défauts cachés ou une tentative d'escroquerie.

N'achetez pas de produits dont le prix est trop différent du prix moyen de produits similaires.

Ne consentez pas à payer une caution ou une avance douteuse. En cas de doute, n’hésitez pas à demander des précisions, des photos et des documents supplémentaires, vérifier l'authenticité des documents ou encore poser des questions.

C'est l'arnaque la plus répandue. Des vendeurs malhonnêtes peuvent demander une avance sur le montant total pour « réserver » votre achat. De cette manière, ils peuvent recueillir un montant considérable, puis disparaître.

- Faire un prépaiement sur la carte

- N'effectuez pas de prépaiement sans établir de documents confirmant le transfert d'argent si le vendeur vous semble suspect au cours de vos échanges.

- Transfert de l'argent sur le compte séquestre

- Méfiez-vous de ce genre de demandes, il est très probable que vous soyez en train de communiquer avec un fraudeur.

- Virement sur le compte d'une société avec un nom similaire

- Soyez vigilant(e), des fraudeurs peuvent se faire passer pour des entreprises connues en introduisant des modifications mineures dans le nom. Ne transférez pas d'argent en cas de doute sur le nom de l'entreprise.

- Substitution de ses propres coordonnées dans la facture d'une entreprise réelle

- Avant d'effectuer le virement, vérifiez que les coordonnées indiquées sont exactes et qu'elles appartiennent à l'entreprise indiquée.

Coordonnées du vendeur

Allemagne

Allemagne

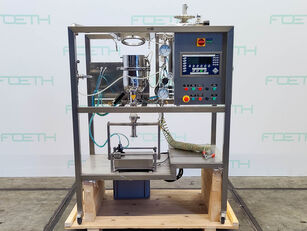

Putzmeister sewage sludge conveyor system with a maximum delivery rate of 6-7 t per hour and a pressure of 100bar (including pumping)

Is no longer in the pit in the pictures

has been

cleaned and stored

Fully functional and hardly used

Design data (organic)

Medium

Conveying medium: Sewage sludge

Material definition (Fluid I / Fluid II) (*1): Fluid 2

Dry matter content: 25 to 30%

Type of dewatering: Centrifuge

Precipitant (*4): Polymer

Maximum particle size: 5 mm

Type / size of foreign bodies (*6): Wood

glass

stones / 80 x 80 x 80 mm

Flowability: Like moist soil

Temperature of the medium: +5 to +20 °C

Density of the medium: 0.9 to 1.1 t/m³

pH value: 6 to 8

Gas formation: None

Loss on ignition (*5): < 40%

Rheological behaviour: Thixotropic

Aggressive: No

Abrasive: Yes

Corrosive: No

Sticky: Yes

Further data

Installation location: Outside

Ambient temperature: -5 to +35 °C

Installation altitude: < 1,000 m.a.s.l

Operating time: 24 h/d

Explosion protection (*2): None

Zone classification (*3): No zones defined

Notes

*1 Material definition according to the Pressure Equipment Directive 2014/68/EC

*2 In accordance with Directive 2014/34/EC of the European Parliament and of the Council of 21 April 2016

on the harmonisation of the laws of the Member States relating to equipment and protective systems intended for

intended use in potentially explosive atmospheres

*3

*4 When conditioning with FeCI3 or lime

a higher pressure loss must be expected

*5 For sewage sludge

the organic content should be < 50%

*6 Frequency of foreign bodies: max. 1% [vol. %] of the material flow

Functional description and design features

PSP silos are complete systems for picking up

storing and discharging conveyed goods. They essentially consist of

of the silo body with supporting structure

a special silo floor with discharge system

(sliding frame and discharge and pre-pressing screw for feeding a thick matter pump). Depending on the

Depending on the customised system

assemblies such as an assembly platform

insulation/heating or instrumentation are added

Design

Angular design

Capacity: 42 m³ (geometric) / Please note: The net capacity depends on the

Bulk cone / dry matter content

Silo dimensions: 5500 mm x 3500 mm x 2200 mm (WxLxH) with upstand

Height to silo floor: approx. 1040 mm (substructure height)

Total silo height: approx. 3240 mm

including substructure

Rated pressure: Unpressurised

Material

Floor: S355JR G3 (due to increased wear)

Sliding frame: S355JR G3

Other: S235JR G2

Note: An on-site ‘pit’ with a depth of X m is required for the silo

calculated from ground level lorry access

Equipment

Silo prefabricated for bolting / welding at the place of use

Silo body made of sheet steel in welded

site-fabricated or workshop-prefabricated design

Silo floor as flat floor in welded design

stiffened with profiles

with additional welded-in flange for mounting the bolted discharge auger

with hold-down brackets for mounting the Putzmeister discharge system (sliding frame)

With eyelets for attaching mounting aids for the discharge auger

The supporting structure of the silo is designed for good accessibility of the area under the silo

Connections / openings

Silo lid

1 nozzle for fill level measurement

2 nozzles for aeration and ventilation

1 nozzle for CH4 monitoring

Silo

1 nozzle DN 50 flange for waste water from pit sump

1 DN 800 manhole near the flat floor

with screw cap and hinge

The execution is carried out in accordance with an execution description drawn up by PSP

which will be confirmed by the

confirmed by the client within 10 days

without legal obligation on the part of the client

Additional equipment

Splash guard

Anchor boxes

Maintenance platform

Sliding frame PDSL5535

1.00 Sliding frame PDS L 5535

Functional description and design features

A sliding frame made of a bevelled special profile is moved back and forth over the flat silo floor by a hydraulic cylinder

back and forth over the flat silo floor. During the forward movement

the inclined profile edge underruns the material

which is conveyed to the discharge screw

is conveyed to the discharge auger by the driving edge. The sliding frame supports the even and complete

complete sludge discharge into the silo discharge screw and prevents bridging of the medium. Due to the

The even lowering of the silo contents ensures that the sludge is discharged as in a mass flow (first in

first out)

and segregation is prevented

The necessary projection for the drive is approx. 2.80 metres

The lifting speed of the discharge sliding frame can be infinitely adjusted manually to optimise the operating behaviour

operating behaviour. A stuffing box seal and (optional) automatic centralised grease lubrication ensure that the system is sealed against the conveyed material

of the system against the conveyed material

The PDSL series is price-optimised

Installation in rectangular or square steel silo with flat base

Silo dimensions (lxw): 5,500 x 3,500 mm

Cylinder stroke: 800 mm

Weight of the frame: 1.2 tonnes

The silo discharge system consists of

Discharge sliding frame made of special profile S 355

in two or three sections depending on size for transport and easy assembly

with bolted connection

Double-acting hydraulic cylinder

short design

with coupling rod (multiple chrome-plated)

clamping coupling

clamping flange and driver

Spherical cap for aligning the hydraulic cylinder during assembly

Special seals and guide bands as well as contact protection for coupling rod

Two non-contact limit switches on the hydraulic cylinder for stroke reversal

Blockage monitoring

Automatic centralised grease lubrication via the thick matter pump lubrication system

Electrical and hydraulic controls

Safety devices

The proper functioning of the discharge sliding frame is monitored by non-contact limit switches and control of the lifting time

and control of the lifting time. If the set lifting time is exceeded

the lift reverses automatically and a fault signal is issued

(without interrupting operation)

The hydraulic circuit is pressure-monitored. In the event of a blockage of the discharge sliding frame

the stroke is reversed automatically

stroke reversal takes place automatically

When planning

please consider the space required for the hydraulic cylinder outside the silo as well as a free space for removal

for removal

1.00 Sales accessories PDSL Auto.grease.central.lubrication. w. stopper. Additional component

Surcharge for extending the centralised grease lubrication system of the slurry pump with lubrication circuits for

PDSL sliding frame

Incl. proportional pipework

bulkhead strip and small parts

Discharge screw SHS 3232 SH

1.00 SHS Series / Type SHS 3232 SH

The SHS silo discharge screw is designed to convey highly viscous materials from a silo with a positive inlet pressure into the downstream piston pump

positive inlet pressure into the downstream piston pump. This ensures an optimum filling level of the piston pump

is ensured

Drive type: hydraulic

Max. discharge capacity: 40 m³/h

Speed: max. 25 rpm

Torque: max. 2 x 3,500 Nm

Inlet flange: 3,200 x 580 mm

Outlet flange: 720 x 720 mm

Screw diameter: 315 mm

Screw pitch: 250 mm

Empty weight: approx. 3,200 kg

1.00 Sales accessories SHS pressure sensor -1- +4 bar NEX

1.00 Sales accessories SHS Auto.grease central lubrication w. stopper indicator Additional component

Surcharge for the extension of the grease central lubrication of the thick matter pump by lubrication circuits for

Discharge system SHS

Incl. proportional pipework

bulkhead strip and small parts

Sludge pump KOS 1040 HP

1.00 KOS 1040 HP

Putzmeister KOS high density solids pumps with S-pipe are the first choice for transporting slurries and high viscosity

high dry matter content and high viscosity

Machine type: KOS 1040 HP

Max. Delivery rate: 4 m³/h (at 80 % filling level)

Max. Max. delivery pressure: 100 bar

Diameter of the delivery cylinder: 150 mm

Stroke length: 1,000 mm

Pressure connection for connecting the delivery line: ZX 125

Wear parts: DURO 22

Dimensions (LxWxH): 4,100 x 1,200 x 1,100 mm

Dimensions without options

Weight approx.: 2,500 kg

Additional information

Incl. electrical grease central lubrication

Wear protection of the delivery cylinders: Hard chrome-plated

coating thickness: 250μm

1.00 Flow rate theo.max. delivery rate: 5 m³/h @ 100% filling level

1.00 Delivery pressure eff.max. delivery pressure: 100 bar (max.)

1.00 Piston seal Material of delivery piston: NBR

1.00 Centralised grease lubrication Lubrication: Electric centralised grease lubrication

1.00 Sales accessories Pumps Oil pan for 1040 pump

Dimensions without optionsThe pump frame is equipped with a removable oil pan. This prevents any hydraulic oil

This prevents hydraulic oil from spilling onto the floor and ensures a clean and safe working environment

Material: galvanised steel

with handles for removing the tray

Incl. connection for a drain ball valve for targeted draining of impurities

1.00 Sales accessories Pumps Height adjustment for pump 1040

Weight approx.: 2,500 kg

Additional information

Incl. electrical grease central lubrication

Wear protection of the delivery cylinders: Hard chrome-plated

coating thickness: 250μm

1.00 Flow rate theo.max. delivery rate: 5 m³/h @ 100% filling level

1.00 Delivery pressure eff.max. delivery pressure: 100 bar (max.)

1.00 Piston seal Material of delivery piston: NBR

1.00 Centralised grease lubrication Lubrication: Electric centralised grease lubrication

1.00 Sales accessories Pumps Oil pan for 1040 pump

Up to 8 bearing blocks are welded or bolted to the pump frame. A stainless steel

foundation

a stainless steel height adjustment is screwed in

The advantages of this solution are

Unevenness in the foundation can be easily levelled out

Simplified installation with several components on top of each other

The Putzmeister height adjustment allows height adjustment from -12 to + 11 mm

1.00 Sales accessories Pumps Foundation anchor M20 with adhesive cartridge (HA + pump)

1.00 Sales accessories KOS pump funnel GS-LCB KOS 1040 Surcharge

1.00 Colour Colour: MB 1227 (chrome yellow)

1.00 Locking gate valve version Locking gate 720x720x120 manually operated

w. limit switch NEX PD

A gate valve can be used to shut off parts of a system for a variety of reasons. The

gate valve is installed either under a silo

bunker etc. in the inlet of the Putzmeister pump

This is advantageous for carrying out any maintenance work in the pump hopper when the silo is full

The valve blade is opened or closed manually

The open/closed status is monitored by proximity switches

Technical data

720 x 720 120

Incl. limit switch

1.00 KOS Pump type: KOS 1040

1.00 Delivery cylinder length: 1,000 mm

Hydraulic unit HA 75 CI

1.00 HA 75 CI

Hydraulic unit for continuous operation and the following design data

Oil tank volume: 600 litres

Voltage: 400 V / 50 Hz

Engine speed: 1,480 rpm

Dimensions: (LxWxH): 2,700 x 1,400 x 1,700 mm

Dimensions without options

1.00 Cooler HA-CI Cooler version: Oil-air cooler (with electric motor)

1.00 Hydraulic unit colour Colour: MB 1227 (chrome yellow)

standard

1.00 Hydraulic oil Hydraulic oil: HLP 46 (standard)

Switch cabinet SEP 75

1.00 SEP 75

The switch cabinet contains the power and control section of the PSP scope of delivery. It complies with the current

current ISO

DIN

VDE and UVV regulations

General information

Dimensions: 1,200 x 2,000 x 500 mm (incl. base plate)

Protection class: IP 55

Design: 2 (common mounting plate

cable entry into the switch cabinet from below)

Material: painted steel (if stainless steel version is not ordered as a separate option)

Colour: RAL 7035 (light grey)

Equipment (power section)

Power supply with main switch

Motor protection

Motor temperature protection (PTC relay)

Automatic circuit breakers

Equipment (control section)

PLC: Siemens S7 (unless otherwise described)

HMI: 15 touch operating panel (Putzmeister OP151)

Communication to the control room via

Potential-free contacts / Ethernet

Key switch (local-0-remote)

Fault light

Emergency stop button with safety relay (PNOZ) and associated button (blue) for acknowledgement

1.00 Control cabinet version Stand-alone control cabinet version

1.00 Control cabinet design Cable entry: From below

1.00 Electrical control system PLC control system Siemens S7-300

1.00 Electrical control system Signal exchange: Pot. free contacts

Find more here

afficher les coordonnées

Contact us at

afficher les coordonnées